Excellence in Precision Engineering.

High-quality steel products tailored to your needs.

Reliable sourcing and timely delivery.

Quality Assurance

We prioritize quality in every aspect of our production process, ensuring that our steel products meet the highest standards. Our commitment to excellence guarantees durability and reliability for our clients.

Innovative Solutions

Our team is dedicated to providing innovative solutions tailored to your specific needs. We invest in advanced technologies to enhance our production capabilities and meet diverse customer demands.

Customer-Centric Approach

At our core, we believe in building strong relationships with our clients. Our customer-centric approach ensures that we listen to your needs and provide exceptional service at every stage.

Our Offerings: Comprehensive Steel Solutions

Tailored solutions for all your steel processing needs.

Bright Bar and Annealed Steel

- 2 continuous annealing furnaces + 24 centreless grinders: Stable, high-efficiency steel processing guaranteed!

- Custom annealing solutions (spheroidizing/softening/stress relief) for bearing/spring/alloy structural steels!

- 50k tons annealed steel + 20k tons peeled bright bar yearly; φ10-300mm × 2-9m bars available!

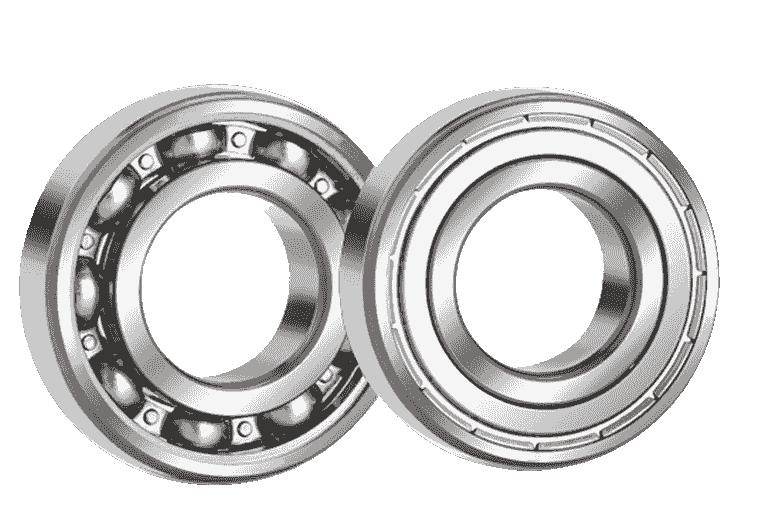

Bearing Steels

- Certification Status: The products have obtained certifications from enterprises including Sweden's SKF, Germany's Schaeffler (which owns brands such as LUK, INA, and FAG), Japan's NSK and KOYO, and France's SNR.

- Product Characteristics: The bearing steel is professionally designed, featuring outstanding performance and reliability.

- Application Advantages: It can ensure the realization of optimal functions in various application scenarios.

Apring Steels

Advantages of Our Company's Spring Steel

- Strong Performance and Scene Adaptability: It combines high elasticity, fatigue resistance, and high yield strength. Some models have heat-resistant/corrosion-resistant properties, which can meet the spring manufacturing needs in multiple fields such as aviation, automobiles, and construction machinery.

- Reliable Both in Process and Standards: It adopts high-purity smelting plus flexible cold/hot forming processes, and strictly complies with international ISO and European EN standards. The quality is controllable and compatible with global procurement specifications.

- Good Choice in Product Range and Cost-Effectiveness: It covers two major mainstream types of spring steel—carbon spring steel and alloy spring steel—with scientific composition ratios. It can be supplied in batches, and high cost-effectiveness is achieved through large-scale management and control, reducing customers' costs.

Alloy Structural Steels

- Strong & Tough CombinedBoasting high tensile strength paired with excellent toughness, ideal for heavy-load and impact-resistant working conditions.

- Easy to Process & ModifyFeaturing superior heat treatment processability, performance can be customized via quenching, tempering and other processes.

- Outstanding DurabilityFatigue-resistant and wear-resistant, it extends equipment service life and cuts down maintenance costs.

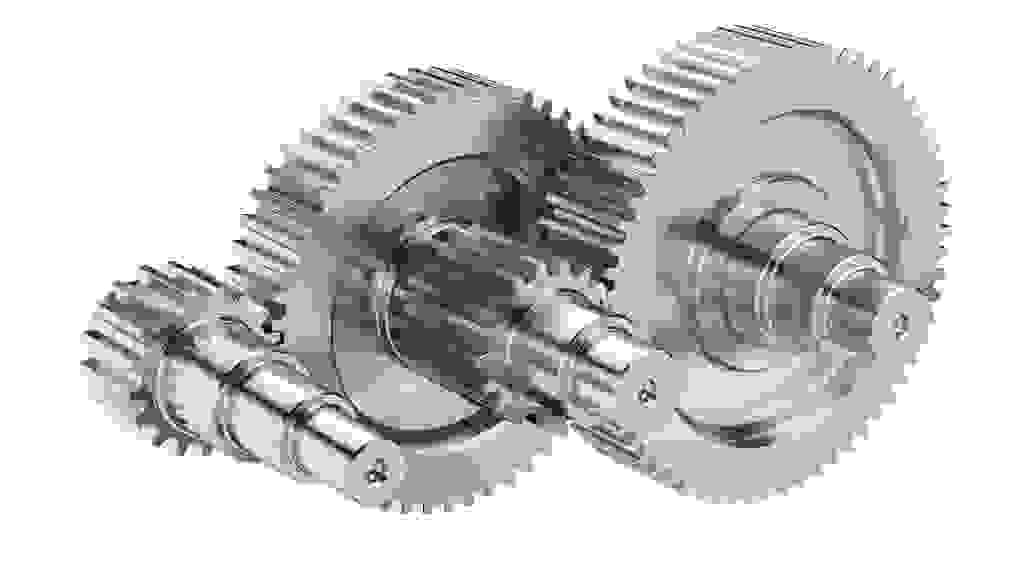

Structural Steel with Harden-ability Bands

- Precise & Stable HardenabilityThe fluctuation range of J9 hardenability band is within 6HRC, ensuring high performance consistency.

- Exclusive for Transmission ComponentsPerfectly meets the manufacturing needs of gears for cars, trucks and various mechanical transmission parts.

- Enhanced Component Service QualityStable hardenability ensures component strength and wear resistance, effectively reducing failure rates.

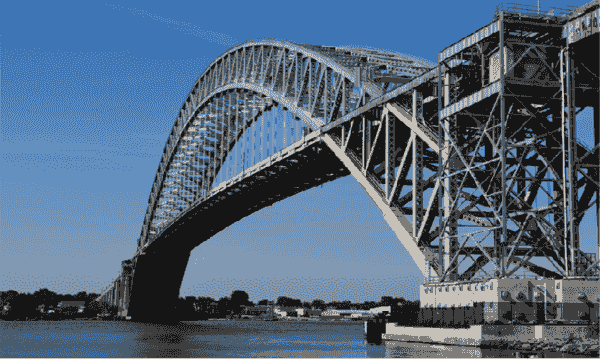

Carbon Structural Steels

- Dual Superior Performance: Excellent mechanical properties and strong machining & forming capabilities.

- Wide Application Scope: Suitable for mechanical structural components, metal products, tools, as well as the construction of plants, bridges, boilers, vessels and more.

- Superior Reliable Quality: Meets the stable service requirements of various load-bearing and pressure-bearing components.

Cold-Heading Steels

- Full Coverage of High-Strength GradesAvailable in grades 8.8 and 9.8, meeting the requirements of high-standard fastener components.

- Exclusive for Fastener ManufacturingPerfectly suited for producing standard parts and fasteners such as bolts and nuts.

- Excellent Process CompatibilityOptimized for cold-heading processing, ensuring superior forming quality and structural stability of components.

WORKSHOP

We harness state-of-the-art machinery and the latest technological advancements.

PRODUCTION FACILITY

Excellence in Precision Engineering

Combined Drawing Machine

Our company is equipped with multiple production lines of combined drawing machines. They feature high processing precision, high production efficiency, and well-guaranteed product quality.

Box-type Annealing Furnace

Box-type Annealing Furnace – Precise Temperature Control & Uniform Annealing, Empowering Metal

Heat Treatment Process Upgrades with Stable Quality and Doubled Efficiency!

Pit-type Annealing Furnace

Pit-type Annealing Furnace

Chain-type Drawing Machine

Wire Coil Shot Blasting Machine

Bar Shot Blasting Machine

Straightening and Cutting Machine

High-Speed Circular Sawing Machine

Vertical Two-Roll Straightening Machine

Vertical Two-Roll Precision Straightening Machine

Nine-Roll Straightening Machine

Sawing Machine

Grinding Machine

Combined Drawing Machine

NEWS

State-of-the-art equipment & cutting-edge processes, 100% compliant with industry standards & specifications.

December 23, 2025 · Our StoryFoshan Liwei New Materials Technology Co., Ltd. was founded with a vision to revolutionize the...December 23, 2025 · Our StoryToday, Foshan Liwei New Materials Technology Co., Ltd. stands as a leader in the steel processing...December 23, 2025 · Our StoryAs demand for precision steel components increased, we expanded our operations to include...December 23, 2025 · Precision Steel ProcessingWe offer expert welding services that combine skill and technology to create strong, durable...December 23, 2025 · Precision Steel ProcessingOur advanced cutting techniques ensure that every piece of steel is processed with precision....December 23, 2025 · Precision Steel ProcessingOur surface finishing solutions provide a perfect blend of functionality and aesthetics. We offer...What Our Clients Say

Feedback from our valued customers.

Outstanding Quality

The precision and quality of the steel products exceeded our expectations. We are extremely satisfied with the service we received.

Exceptional Service

The team was very responsive and helpful throughout the entire process. Their attention to detail made all the difference.

Reliable Partner

Foshan Liwei has proven to be a reliable partner for our steel supply needs. Their commitment to quality is evident in every order.

Contact Us

We welcome your inquiries. Let's collaborate for precision and quality.

Xinde Industrial Zone, Hexi, Yanbu, Dali Town, Nanhai District, Foshan City9:00-18:00+86-13928502929(whatsapp)Select...

©2025 - Proudly built with Strikingly